As a primary sensor commonly used in temperature measurement, thermocouple is widely used in many industries because of its wide measurement range, simple principle, and installation easily. In the entire production process control, the role of temperature measurement, adjustment and control is indispensable.

1. Principle

The basic principle of temperature measurement for thermocouple is based on the principle of thermoelectric effect(Seeback effect). Connecting two different metal conductors to form a loop. If the connected bright spots have different temperatures, an electromotive force will be generated in the measured loop to form a current. This is the thermal effect in thermocouple temperature measurement. Depanding on this principle, the thermoelectric potential value can be directly and effectively measured. The thermoelectric effect have to meet two conditions: first, the measured medium must meet the thermoelectric characteristics of thermocouples require that the bare thermocouple wire material has good electrical conductivity; second, there must be a corresponding temperature difference between the thermocouple measuring and reference junctions.

2. Advantage

(1) The accuracy of temperature measurement is relatively high. According to IEC ans ASTM standards, the error range of Class 1/SLE is about ±0.4%t, and the error range of class 2/Standard can also reach ±0.75%t for type K,N,J,T,E. Others with higher measurement accuracy, such as S graduation have higher measurement accuracy;

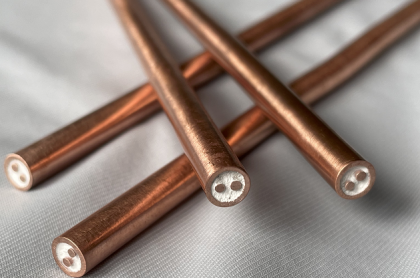

(2) The structure is relatively simple and easy to maintain. Thermocouple’s working principle determines the simplification of its structure and the convenience of maintenance. Its components include electrodes, terminals, insulators, sheaths, etc.;

(3) The response time is fast. Due to its structural composition, it will not generate excessive thermal inertia during the temperature measurement process, and ultimately make it respond quickly during the entire dynamic measurement process;

(4) The signal can be transmitted over a long distance, which is convenient for centralized detection and automatic control. It is now widely used in conjunction with the DCS system;

(5) It can measure partial temperature or even measure "spot" temperature. This is more advantage than thermal resistance.

3. Method

In the overall application process of thermocouple , in order to ensure their measurement results, that is, stability and accuracy, it is necessary to consider the installation specifications , the material requirements of thermocouple elements, and the thermcouple compensation wires to ensure the measurement results’ stability and accuracy. Strictly control the quality to ensure the measurement advantages of thermocouple are maximized.

(1) Requirements for thermocouple installation position

A. The installation position of the thermocouple should be horizontal and vertical to the ground of the operation platform to prevent high temperature from affecting production;

B. Thermocouple has a good stability in the range of the applied medium, it is on the center line of various mediums, and should be opposite to the direction of the fluid to be detected;

C. If there is an elbow area in the pipeline of the fluid medium, thermocouple should be installed at the bend;

D. If thermocouple is applied in a horizontal position, it should be fixed firmly with auxiliary refractory materials or metal brackets for steady fix.

(2) Basic conditions for making thermocouple materials

A. The material has good temperature-sensing characteristics, and the electrical conductivity and electromotive force should be called a relative proportional relationship or an approximate linear functional relationship;

B. The operating temperature range of thermocouple should be able to meet various production requirements and application conditions;

C. The material of the thermocouple should have good electrical conductivity, and the resistivity and heat capacity should be controlled within a small range;

D. The thermoelectric performance is stable, not restricted by the environment and other conditions, to easily process and reproduce;

E. The materials used to make thermocouple need to have corresponding characteristics, the price is suitable for the actual needs of production, and it is convenient for widely application and production.

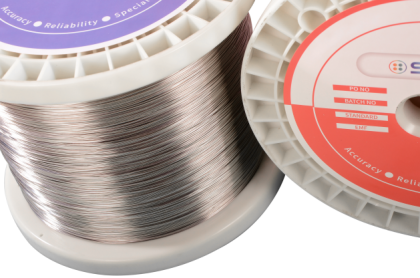

(3) The problems to be noticed when using the thermcouple compensation cable

The manufactured thermocouple and the thermocouple in use should be checked regularly while their appearance is strictly inspected. The unused thermocouple require no cracks on electrodes and the diameter is uniform and straight , thermocouple should well protect related material to avoid corrosion or defects. The thermocouple and the measuring bracket should be firmly welded without any signs of looseness, and the surface should be free of pores, smooth and free of inclusions.

A. The selection of thermocouple compensation wire should correspond to the type of thermocouple;

B. When the compensation wire is connected to the thermocouple, the positive and negative poles should be well connected, and there should be no temperature difference between the two connected points;

C. The thermocouple compensation cable should not exceed the operating temperature range to eliminate additional errors;

D. The diameter of the thermocouple compensation cable should be selected according to the different requirements of the equipped instrument to ensure the accuracy of the measurement.

4. Conclusion

As a typical self-generating sensor, thermocouple has been widely used in the field of temperature measurement,. but it also has certain shortcomings, especially in the application process. If we do not pay attention to the relevant installation details during , it will inevitably have a certain negative effect on the start-up and normal operation of the entire monitoring system, which requires us to pay attention to it in the process of its application.

Related products: mineral insulated compensating cable

IPv6 network supported

IPv6 network supported