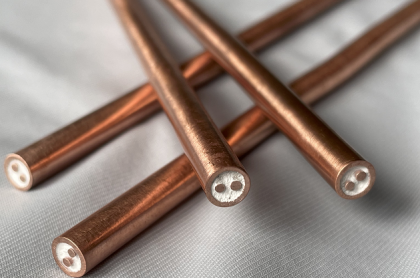

Mineral insulated thermocouple cable is used to insulate

thermocouple wires from one another and from the metal sheath that surrounds

them. The MIMS cable has two or four thermocouple wires running down the middle

of the tube, the tube is then filled with magnesium oxide powder and compacted

to ensure the wires are properly insulated and separated.

It has some advantages: first, the response time is fast, the

minimum number of milliseconds can be reached, which is suitable for the

detection of microcomputer control; second, the chemical stability is good and

the deviation of the indexing drift is small after using for a long time, thus

due to long life; third, the mechanical properties is good which can withstand

strong vibration and impact; fourth, the high pressure resistance is greater

than 3000MPa; fifth, the insulation properties is good under high temperature

conditions; sixth, it is suitable for measuring temperature and automatically

controlling temperature under the condition of high pressure, high temperature

at the same time; seventh, it can be bent freely with small outer diameter,

suitable for complex, narrow bending, miniaturized occasions to measure and

control temperature; therefore, mineral insulated cable has been widely used.

The manufacturing process of mineral insulated cable is combined

the bare thermocouple wire, insulating material (generally magnesium oxide powder)

and sheath tube to form a solid body. After the assembly, the drawing machine

is used (chain puller and cylinder puller) toreducethe diameter

gradually from the maximum diameter of 23mm to 8mm and the minimum diameter is

reduced to 0.25mm. During each diameter reduction process, the metal is

compressed and deformed, a deformation stress is generated, the cable will be

broken if the deformation stress is not eliminated. In order to eliminate the

deformation stress, it is necessary to anneal in a heat treatment furnace to

restore the metallographic structure, and the reduction process is continued

until the desired outer diameter is reached.

Since the requirement of material accuracy is very strict,currently

we imply box furnace, the belt type annealing furnace or the short circuit

annealing. But the results does not reach the stability process

requirement, so the high grade cable can not be come out.

We provide a method for manufacturing mineral insulated cable

with gas shield to achieve the goal of high quality and low production cost.

The thermocouple wire is inserted into the prefabricated hole of the insulated

material and the metal sleeve is sleeved on the outside of the insulating

material, its diameter is reduced and heat treated to reach the outer diameter

meeting the requirement.

The thermocouple material is heated and cooled equally,

uniformly, so that the entire wires can be reached to data requirements by

continuous heat treatment. By gas protection and continuous heat treatment, the

qualified product rate is above 70%, so the production efficiency is increased

and the cost is reduced.

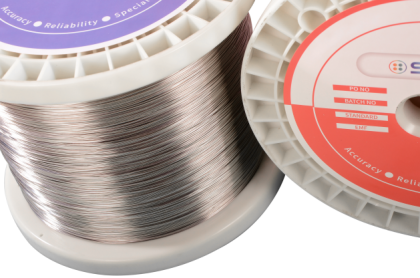

When feeding the qualified thermocouple wire is first

straightened and cleaned, to be penetrated into the hole of pre-made Mgo powder

porcelain column, then is inserted into the inner hole of the metal sleeve, the

diameter reduction process will bestartedafter the

assembly is competed. The diameter of 23mm to 16mm is rolled into the rolling

point machine, and then penetrated into the mold to reduce the diameter on the

chain drawing machine until the diameter is reduced to 8mm, the roller drawing

machine is used to reduce the diameter to 3mm instead when the diameter is less

than 8mm,the vertical drawing machine is used to reduce less than3mm

until 0.25mm. After each reduction, hardening occurs due to metal deformation

stress, which need to be softened by heat treatment to restore the

metallographic structure. After the heat treatment, the reduction need to be

continued to the required diameter. The protective gas in the heat treatment is

usually a mixed gas of nitrogen or hydrogen, so the bright surface can be

reached.

The temperature of heat treatment is also critical, its range is

750-1200C and the temperature intelligent meter is used to automatically

control the display and control temperature.

Whether the heat treatment step using gas protection is related

to the surface quality of mineral insulated cable. Because the MIMS cable is a

precision material used in automated instruments, its surface quality is very

important, not only its appearance does not allow metal spalling, pitting or pulling

defects, but also the outer surface brightness to reach the mirror surface.

If the gas protection is not used, the metal will be generated

an oxide layer above 750C, the surface of mi thermocouple cable will cause

metal peeling and pitting on the surface. At the same time, due to repeated

heat treatment, the outer thickness is thinned, which affects the mechanical

strength that reduces the service life. Therefore, the whole process of heat

treatment must be continuous and protected by gas.

In the above mentioned reduction treatment, the diameter is

gradually reduced from a large diameter of 23mm to a minimum of 0.25mm, and

molds having different apertures are to be disposed. In order to enable the mi

thermocouple material to penetrate into the hole of the mold, the tipping

machine must be designed according to the different specifications. According

to the reduction ratio, the tipping machine has multiple holes which require a

reasonable compression ratio and rolling. The surface is smooth and no burrs to

avoid pulling the mold, The chain puller uses pneumatic automatic clamping

device and trolley automatic shuttle device to reduce labor intensity and

increase the production efficiency.

During the drawing process, the drawing die and the thermocouple

material need to be well lubricated so that the drawn workpiece is sufficiently

lubricated in the die hole. If the lubrication is poor or the inner hole of the

mold is not smooth, the surface of the coupler is roughened, so a lubrication

device is also required.

From the diameter of 23mm to the minimum of 0.25mm, the type and

quantity of drawing machines and molds can be designed and configured according

to the specific conditions of the production site and equipment. get more information from www.super-instrument.com.

For more special applications, it is recommended to consult our professional engineers, and we can provide more specific suggestions and solutions for you.

IPv6 network supported

IPv6 network supported