Thermocouple compensation wireshave been widely used in thermocouple temperature measurement.Understanding the principle, function, method of action and precautions of the thermocouple compensation wire,we can give full play to the role of the thermocouple compensation wire, otherwise it will be counterproductive. In industrial production, although thermocouple has been widely used in temperature measurement and control as temperature sensors, people are familiar with this, but if you do not pay attention to the correct use method, it will cause great deviations in temperature measurement and temperature control. Even directly causing economic losses, should be taken seriously.

1. Principle

A circuit composed of two different metal conductors A and B connected together is called a thermocouple. If the junction temperature T1 and T2 are different, an electric potential will be generated in the circuit, usually called thermoelectric potential. When the materials of A and B are constant, the thermoelectric potential depends on the temperature difference between T1 and T2. When the materials of A and B are constant, the thermoelectric potential depends on the temperature difference between T1 and T2.

According to the law of thermocouple intermediate conductors, as long as the temperature of junctions J2 and J3 in the right figure are the same, both are T2, and both of connecting wires are the same homogeneous material, and the right and left figures are equivalent.

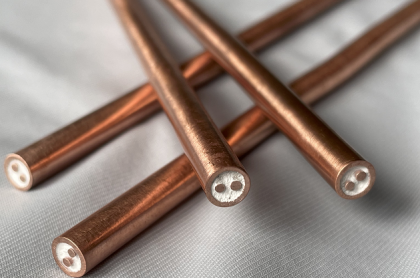

2. Compensation wire

After the thermocouple is installed in the field, it must be connected to the instrument to measure or control the temperature. Since thermocouple is always used some distance away from the measuring or controlling instrument, the temperature at the thermocouple terminal is not the same as the temperature at the input of the instrument. Generally speaking, a reference junction temperature compensation problem is needed, and the compensation wire does not compensate the reference junction, it only extends the reference junction to a specific position for processing, so the compensation wire is also called the thermocouple extension wire. There are two kinds of materials for making compensation wires. One is that within a specific temperature range, the thermoelectric potential generated by the compensation wire is similar to that of the thermocouple to be used, which is called compensation wire; the other is made of thermocouple material, known as extension wires. Such extended wires are obviously not possible for noble metal thermocouple. The compensation wire is an important part of the thermocouple measurement, so the corresponding model must be selected correctly and reasonably, and the compensation wires of different types cannot be mixed.

3. Common errors in use

(1) The positive and negative poles of the thermocouple compensation wire and the thermocouple are reversed

If the positive and negative poles of the thermocouple compensation wire and the positive and negative poles of the thermocouple are reversely connected, and the positive and negative poles of the thermocouple are connected to the positive and negative poles of the instrument correctly, not only does it not play a compensation role, but the error is greater than that of not connecting the compensation wire. It will also be doubled, so the polarity must be paid attention to when the compensation wire is connected.

If the polarity of the thermocouple compensation wire cannot be determined,we can take a piece of compensation wire, remove the insulation at one end, twist them together, put them in a hot water cup, and measure the two wires at the other end with the lowest DC voltage range of an ordinary multimeter. The positive and negative of the measured voltage will be displayed, and the positive pole of the signal is the positive pole of the compensation wire.

(2) Incorrect type of compensation conductor used

The same type of compensation wire is matched with the same type of thermocouple. If the type of compensation wire selected is wrong, errors will also occur.

(3) Compensation wire mixed with common wire

In practical applications, it is often found that the compensation wire is not long enough to be connected with an ordinary wire, or a section of ordinary wire is connected after the compensation wire is broken. Usually, the differential potential of the base metal thermocouple is greater than that of the noble metal thermocouple, and the influence of the noble metal thermocouple is greater.

4. Precautions

(1) Choices

The compensation wire must be correctly selected according to the type of thermocouple and the occasion. For example, K-typethermocouple should choose the compensation wire of K-type, and select the working temperature range according to the application occasion. Usually the working temperature of KX is -20 ~ 100 ℃, and the wide range is -25 ~ 200 ℃. The error of normal level is ±2.5 ℃, and the error of precision level is ±1.5 ℃.

(2) Connecting

As close as possible to the two junctions of the thermocouple terminals, try to keep the two junctions at the same temperature. The temperature of the connection with the instrument terminal should be as consistent as possible. Where there is a fan in the instrument cabinet, the joints should be protected so that the fan does not blow directly to the joints.

(3) Use length

Because the signal of the thermocouple is very low, which is at the μ V level, if the distance used is too long, the attenuation of the signal and the interference coupling of strong electricity in the environment can distort the signal of the thermocouple, resulting in inaccurate measurement and control of temperature, serious temperature fluctuations will occur.

Usually, it is better to control the length of the thermocouple compensation wire within 15m. If it exceeds , it is recommended to use a temperature transmitter to transmit the signal. The temperature transmitter converts the potential value corresponding to the temperature into a DC current transmission, and has strong anti-interference.

(4) Setting

Compensation wires must be routed away from power lines and interference sources. Where it is unavoidable to cross, try to use crossing as much as possible instead of parallel.

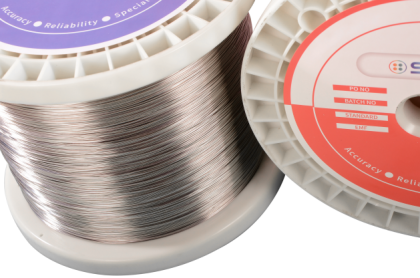

(5) Shielded compensation wire

In order to improve the anti-interference performance of thermocouple connecting wires, shielded compensation wires can be used. The effect is better for occasions where there are many interference sources on site. However, the shielding layer must be strictly grounded, otherwise the shielding layer will not play the role of shielding, but will enhance the interference.

IPv6 network supported

IPv6 network supported