The principle of thermocouple temperature measurement is based on the thermoelectric effect, two different conductors are welded at one end and connected at the other end to form a closed loop. When there is a temperature difference between the two ends, the circuit generates thermal electromotive force (also known as thermal electromotive force). The phenomenon that thermoelectric potential is generated by temperature difference is called "thermoelectric effect". These two different conductors combine to form a thermocouple.

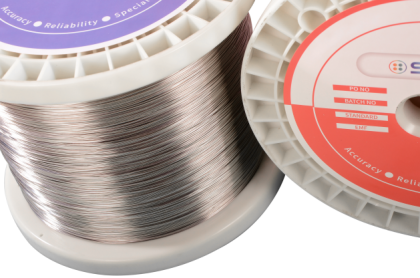

According to the above principle, the following conditions must be met for thermocouple to generate thermoelectric potential: thermocouple must be composed of two conductor materials with different properties but meeting certain requirements; there must be a temperature difference between the working end of the thermocouple and the reference end. The greater the temperature difference between the working end and the reference end of the thermocouple, the greater the total thermoelectric potential. The materials required to select two different conductors of thermocouple must meet the following conditions: high physical stability and chemical stability; small temperature coefficient of resistance and high conductivity; the generated thermoelectric potential and temperature should be in a linear relationship, the reproducibilityandprocessing performance is good. After understanding the basic principle and structure of thermocouple, it can provide a shortcut for troubleshooting when thermocouple is repaired.

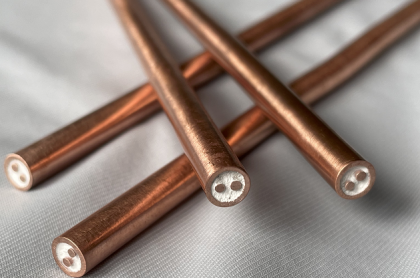

During the visual inspection of the thermocouple, the following aspects are mainly checked: check whether the junction box is in good condition, whether the protective tube is bent or burned; shake the thermocouple gently, and observe whether there is any abnormal sound in the tube. When disassembling and inspecting, check whether the terminal is clean or the screws are loose; pull the thermal electrode out of the protective tube and observe whether the insulating tube is wet, whether the thermal electrode has transverse cracks (inferior thermocouple) or whether the surface has small deep marks like a knife cut (advanced thermocouple); observe whether the color of the thermocouple junction is normal.

The failure of thermocouple in use is generally that the output potential is lower or higher than the actual value, and the thermoelectric potential is sometimes absent or insensitive.

1. Potential is lower than actual value (meter indication is low)

(1) Deteriorated thermocouple electrode or moldy working end

Method: cut off the deteriorated part, re-weld the working end or replace with a new electrode.

(2) Moisture leakage inside the thermocouple

Method: Take out the thermal electrode, dryit and insulate porcelain tube. Check the leakage of the protective tube. Those who fail should repair welding or replace the new protective tube;

(3) Dust between the terminals in the thermocouple junction box or the iron filings are short-circuited

Method:Use a brush to remove dust, remove iron filings, and seal the junction box well;

(4) The connection screw in the thermocouple temperature measurement circuit is corroded, and the circuit resistance is greater than 15Ω

Method: Unscrew the rusted screws and remove the rust with sandpaper. Use a multimeter to test the loop resistance, it should meet the requirement of 15Ω;

(5) Compensation wire wet short circuit

Method:Remove the water between the compensation wire and the protection tube, eliminate the short-circuit point, replace the new compensation wire, and take waterproof and short-circuit prevention measures;

(6) Improper configuration of compensation wire type and thermocouple type

Method:Replace the compensating wire matched with the thermocouple;

(7) The polarity of the compensation wire and thermocouple is reversed

Method: Reconnect;

(8) Improper installation position of thermocouple, shallow insertion depth

Method:Select an appropriate installation location and adjust the insertion depth;

(9) The thermocouple is inconsistent with the scale of the meter

Method:Replace with a thermocouple that matches the scale of the meter;

(10) Thermocouple cold junction temperature is too high

Method:Move the compensation wire for the cold junction of the thermocouple to a place where the temperature is lower and relatively constant or accurately correct the temperature of the cold junction.

2. Potential ishigher than actual value (meter indication ishigh)

(1) Thermocouple is inconsistent with the scale of the meter

Method: Replace thermocouple to match meter;

(2) Thermocouple does not match compensating wire

Method: Replace the compensation wire with one that matches the thermocouple;

(3) Improper installation of thermocouple

Method: Choose an appropriate installation location;

(4) Thermocouple or compensation wire grounded in series with additional ground potential

Method: Check the ground point and fix it.

3. Thermal potential is sporadic (meter indication fluctuates)

(1) The screw securing the thermode at the thermocouple terminal is loose

Method: Tighten the screws at the terminals;

(2) Intermittent short circuits, grounding, disconnections or loose set screws in the thermocouple measurement circuit

Method:Check the thermocouple and compensation wire, eliminate the grounding point and weld the compensation wire and thermal electrode, and tighten the fixing screws.

(3) The thermocouple is swinging due to loose installation

Method:Install the thermocouple firmly.

4. Thermocouple insensitive to changes in thermal potential

(1) Deteriorated thermocouple electrodes

Method: Cut short and re-weld or replace the electrode;

(2) Improper installation of thermocouple

Method: Change the installation location;

(3) Dust on the outer skin of the thermocouple protectionsheath

Method: Remove the thermocouple and remove the dust from the sheath.

5. Attention

(1) According to the scope and object of measurement, select the appropriate thermocouple and protective sheath, cold junction compensator, compensation wire, and secondary instrument. The graduation numbers must be consistent;

(2) The installation location of the thermocouple should avoid being close to hot objects such as furnace doors and places with strong magnetic fields. The junction box of the thermocouple should not be in contact with the measured medium container or pipe wall. The temperature of the cold junction of should generally not exceed 100°C. Do not install thermocouple leads in the same conduit as power cables;

(3) The depth of thermocouple insertion generally requires that the working end be installed as much as possible beyond the center of the pipe by about 5-10 mm, and the working end and the fluid to be measured should be perpendicular or reverse 45°. If this requirement cannot be met and horizontal installation is required, a bracket made of refractory clay or heat-resistant metal should be used for support. The outlet hole of the junction box should be downward to prevent moisture, dust and dirt from entering the junction box due to poor sealing;

(4) The insertion depth of the thermocouple should not be less than 8 to 10 times the diameter of the protection tube itself. Otherwise, the expansion tube should be added;

(5) When the thermocouple is installed on a pressure vessel, its sealing performance must be strictly guaranteed, and the protective sheath with porcelain must avoid sudden heat and sudden cooling to prevent the porcelain tube from bursting. Installation should be in a location that does not interfere with the removal or installation of other equipment;

(6) When measuring the surface temperature of the pipeline, the surface should be kept clean, the hot end should be in good contact with the surface, the installation part should be well insulated, the compensation wire and wire should be shielded, and the polarity should be paid attention to when wiring;

(7) The thermocouple should be checked regularly, and can be used after passing the test.

IPv6 network supported

IPv6 network supported