Thermocouple is a temperature sensing element and a primary instrument. It directly measures the temperature and converts the temperature signal into a thermal electromotive force signal, which is converted into the temperature of the measured medium through an electrical instrument (secondary instrument). The basic principle of thermocouple temperature measurement is that two conductors of different compositions form a closed loop. When there is a temperature gradient at both ends, a current will pass through the loop. At this time, there will be an electromotive force - a thermal electromotive force - between the two ends. This is theSeebeckEffect. Two homogeneous conductors with different compositions are hot electrodes, the end with higher temperature is the working end, and the end with lower temperature is the free end. The free end is usually at some constant temperature. A thermocouple index table is made based on the functional relationship between thermoelectromotive force and temperature; the index table is obtained when the free end temperature is 0°C. Different thermocouple has different graduations. The basic principle of thermocouple temperature measurement: two conductors or semiconductors A and B of different materials are welded together to form a closed loop. When there is a temperature difference between the two junction points 1 and 2 of conductors A and B, an electromotive force is generated between the two, thus forming a large current in the loop. This phenomenon is called the thermoelectric effect. The method of using thermocouple, such as the selection of test points, insertion depth, response time, etc., will all cause measurement errors.

1. Factors

1.1. Effect ofInsertionDepth

1.1.1. Selection ofTemperatureMeasurementPoints

The installation location of the thermocouple & the selection of the temperature measurement point are the most important. The location of the temperature measurement point must be typical and representative for the production process, otherwise the meaning of measurement and control will be lost.

1.1.2. InsertionDepth

When a thermocouple is inserted into the temperature field being measured, heat flow will occur along the length of the sensor. Heat loss occurs when the ambient temperature is low. As a result, the temperature of the thermocouple and the object being measured are inconsistent, resulting in temperature measurement errors. In summary, the error caused by thermal conduction is related to the insertion depth. The insertion depth is related to the material of the protective tube. Because of its good thermal conductivity, the metal protective tube should be inserted deeper (about 15 times the diameter). Ceramic materials have good thermal insulation properties and can be inserted shallower.

1.2. Impact onResponseTime

The basic principle of contact method temperature measurement is that the temperature measuring element must reach thermal equilibrium with the object being measured. Therefore, a certain amount of time is required to achieve thermal equilibrium between the two when measuring temperature. The length of the holding time is related to the thermal response time of the temperature measuring element. The thermal response time mainly depends on the structure of the sensor and the measurement conditions. For gas media, especially stationary gas, it should be maintained for at least 30 minutes to reach equilibrium. The navigation mark stipulates that the heat preservation time of each detection point should be 30 minutes; for liquids, the fastest should be more than 10 minutes.

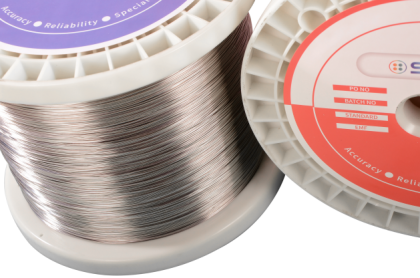

For the measured place where the temperature is constantly changing, especially the instantaneous change process, the whole process only takes 1 second, the response time of the sensor is required to be in the millisecond level. Therefore, ordinary temperature sensors not only lag behind the temperature change rate of the object being measured, but also produce measurement errors due to failure to achieve thermal balance. It is best to choose a sensor with fast response. For thermocouple, in addition to being affected by the protective tube, the diameter of the measuring end of the thermocouple is also a major factor. The thinner the wire, the smaller the diameter of the measuring end, and the shorter the thermal influence time.

1.3. Effect of thermal radiation

The thermocouple inserted into the furnace for temperature measurement will be heated by the thermal radiation emitted by the high-temperature object. It is assumed that the furnace gas is transparent. Moreover, when the temperature difference between the thermocouple and the furnace wall is large, temperature measurement errors will occur due to energy exchange. In order to reduce thermal radiation errors, heat conduction should be increased and the furnace wall temperature should be as close as possible to the temperature of the thermocouple. In addition, attention should be paid to the following during installation:

(1) The installation position of the thermocouple should be as far away as possible from the heat radiation emitted from the solid body so that it cannot radiate to the surface of the thermocouple.

(2) It is preferably equipped with a heat radiation shielding sleeve.

1.4. Effect of increased thermal impedance

If the measured medium is in a gaseous state, the dust deposited on the surface of the protective tube will melt on the surface, causing the thermal resistance of the protective tube to increase; if the measured medium is a melt, there will be slag deposits in the thermocouple during use, which not only increases the response time of the thermocouple, but also makes the indicated temperature lower. Therefore, in addition to regular inspections, frequent spot inspections are also necessary in order to reduce errors.

2. Attention

2.1. InhomogeneousEffects ofThermocoupleWire

2.1.1. The thermocoupleMaterialItself isNotHomogeneous

According to the requirements of the regulations, when the thermocouple is calibrated by the measurement department, the depth of insertion into the calibration furnace is only 300mm.The calibration result of each thermocouple can only reflect or mainly reflect the thermoelectric behavior of the 300mm long wire starting from the measuring end. However, when the length of the thermocouple is long, most of wire is in the high temperature zone. According to the law of homogeneous loop, if the thermocouple wire is homogeneous, the measurement result has nothing to do with the length. However, any wire is not homogeneous, especially cheap metalone, which haspoor homogeneity and are in situations with temperature gradients. The temperature gradient is often irregular and does not necessarily maintain a constant value throughout the entire loop &direction. At the same time, the size and position are constantly changing, and the even wire must remain uniform throughout its entire length so that the potential signal obtained can be trusted.

2.1.2. Inhomogeneity

For newly made thermocouple, even non-uniform thermal electromotive force can meet the requirements. However, aging and contamination may change the uniformity of the thermocouple. Repeated processing and bending will cause processing distortion of the thermocouple, which will also cause it to lose its homogeneity. In addition, when the thermocouple is exposed to high temperature for a long time during use, the thermal electromotive force will change due to the deterioration of the thermocouple wire. When the deteriorated part of the thermocouple is in a place with a temperature gradient, parasitic electromotive force will be generated and superimposed on the total thermal electromotive force, resulting in measurement errors. Armored thermocouple has a good advantage in this regard, and the uniformity of the wire is not easy to change during operation.

3. Thermocouple Deterioration& Service Life

3.1. Deterioration ofThermocouple

The service life of a thermocouple is related to its deterioration. The deterioration of a thermocouple means that aging and deteriorating after use. Thermocouple made of metal or alloys have internal grains that gradually grow at high temperatures. At the same time, the alloy contains a small amount of impurities, and its position or shape will also change. Moreover, it also reacts to reducing or oxidizing gases in the surrounding environment. Along with the above changes, the thermoelectromotive force of the thermocouple will also be extremely sensitive to changes. The deterioration of thermocouple is inevitable.

3.2. Service life

The deterioration of thermocouple is a quantitative process, and it is difficult to quantify it. It will vary with the type of thermocouple, diameter, operating temperature, atmosphere and time. The service life refers to the deterioration of the thermocouple that exceeds the allowable error.

3.2.1. The life ofAssembledThermocouple

In actual use, assembled thermocouple usually has protective tubes. Bare silk is used only in special circumstances. Therefore, in most cases, the life of the protective tube determines the life of the thermocouple. Judgment of the actual service life of thermocouple must be based on long-term collection and accumulation of data under actual use conditions to be able to give more accurate results.

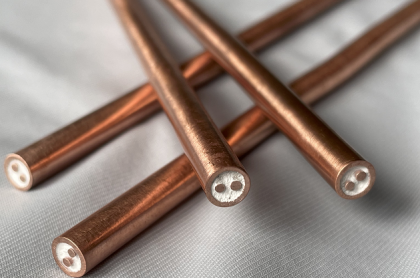

3.2.2. ArmoredThermocouple Life

Since the armored thermocouple is protected by a casing and is isolated from the external environment, the casing material has a great influence on the life. The thermocouple wire and metal casing must be selected according to the purpose. When the material is selected, its lifespan increases as the diameter of the armored thermocouple increases. Althoughit has many advantages over assembled thermocouple, which is prone to deterioration.

IPv6 network supported

IPv6 network supported