Do you know how does K thermocouple conductors are made?

February 03, 2023

The principle of thermocoupleis based onthe

binding ability of metal atoms(ions) to free electrons in metals related to

temperature, different kinds of metal atoms(ions) have different binding abilities

to free electrons. The metal on both sides of the fusion interface after two

kinds of metals are welded together has different binding ability to free

electrons, the large one is positively charged and the other side is negatively

charged. There is electromotive force (EMF) difference between the two sides of

metals that be changed with the temperature, the value of EMF is small but can

be accurately measured.

Thermocouple’s features are widely temperature range, stable

performance, simple structure, fast response and the ability to remotely

transmit 4-20mA signals for automatic control and centralized control.

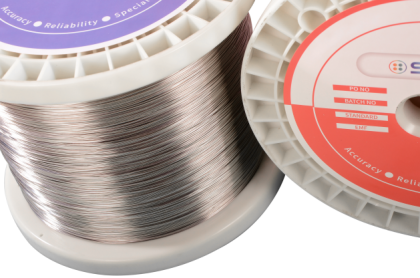

The positive of type K thermocouple conductor is mainly made of

nickel chromium alloys, the negative of type K thermocouple conductor is mainly

made of nickel silicon alloys, its manufactured processes as follow:

thermocouple metal alloys smelting process; thermocouple wire element drawing

process; bare thermocouple wire welding and product testing.

a, The various elemental materials are added together to the

melting equipment in proportion to the thermocouple alloys ingot under the

negative pressure state, and it is subjected to elemental analysis. To ensure

the precision of the composition analysis, the Fe content is required to be

analyzed that need to be controlled within the range of 0.05±0.02%. The vacuum degree is controlled to 10-2

level, which reduces the oxygen content and improves the purity of thermocouple

alloy.

b,The thermocouple alloys firstly are subjected to hot-rolling

into 8mm bar for the drawing process, remove 0.5kgs at the both ends. The pass

rate of the wires should be controlled at 60%, the drawing lubricant

applications having reducing properties can ensure there is no serious

oxidation during annealing.

c,The production of type K thermocouple alloys is divided into

the production of nick chromium alloy wire and nickel silicon alloy wire, the

two kinds of wires are welded together forming the closed loop.

IPv6 network supported

IPv6 network supported